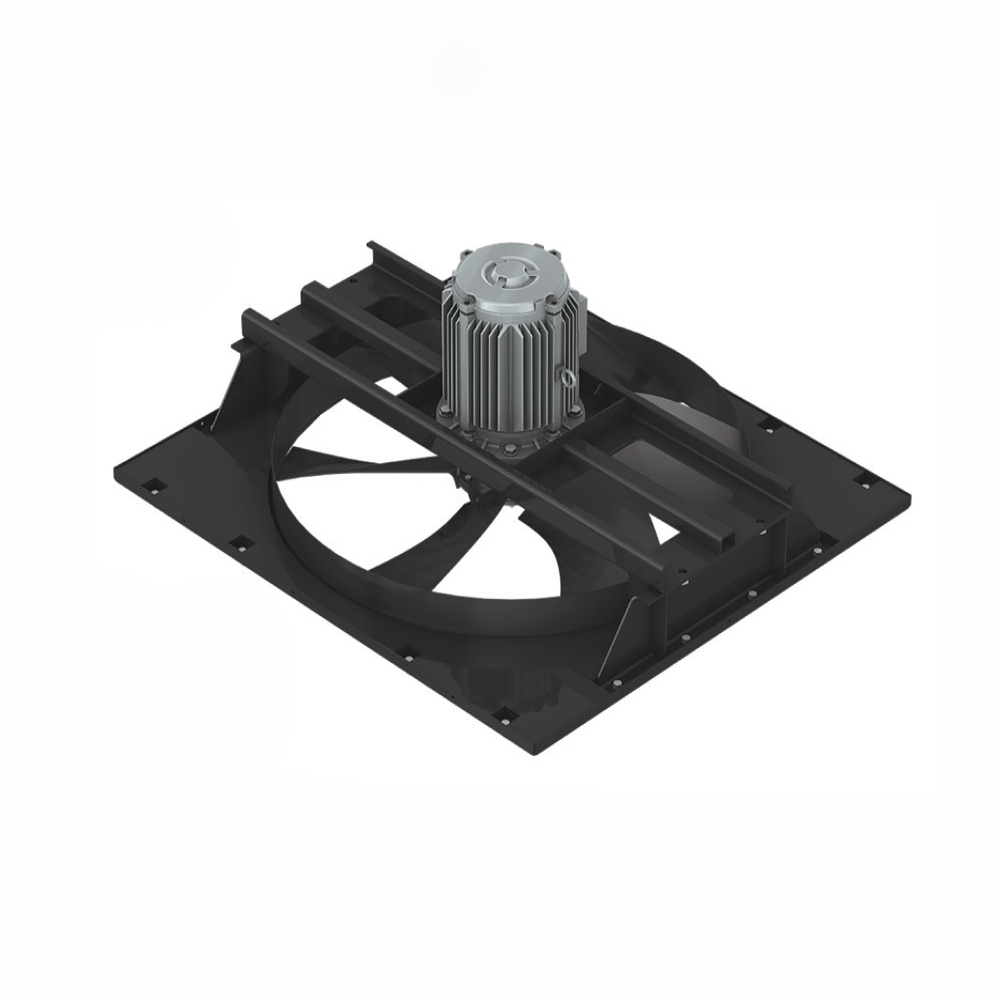

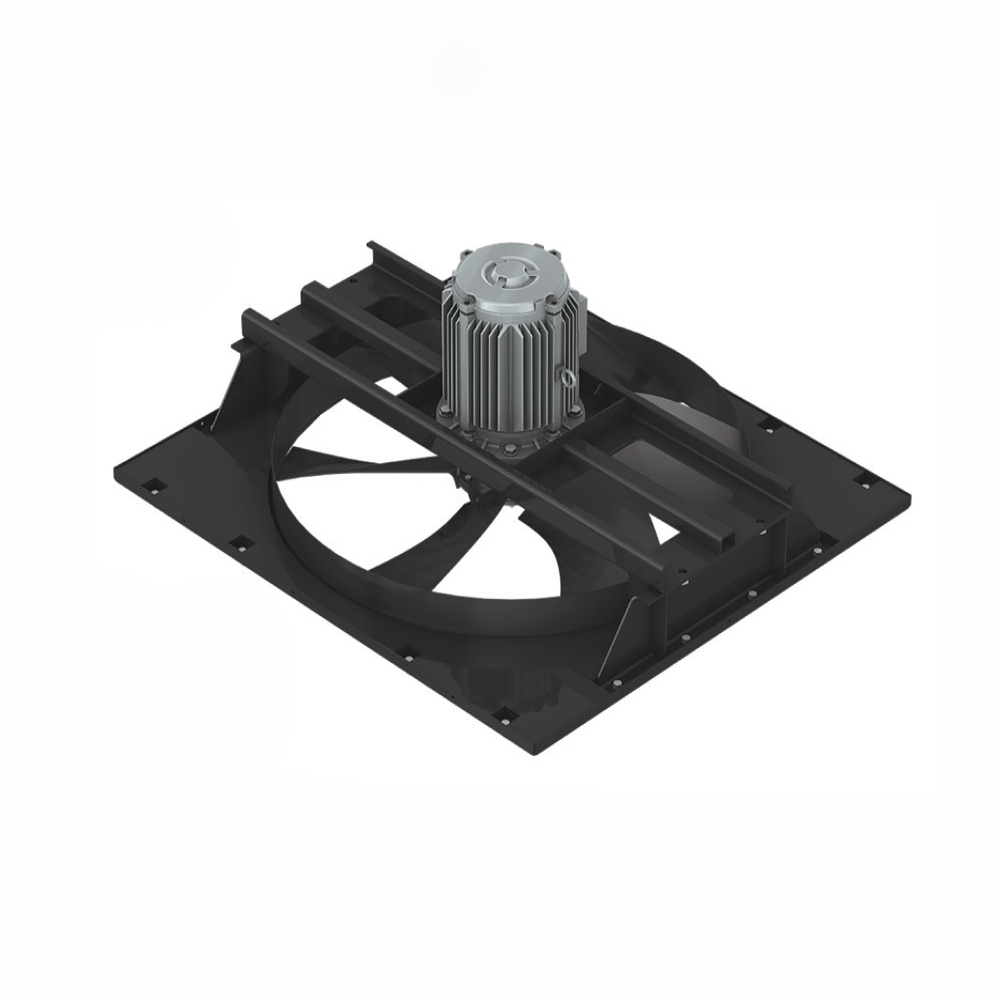

Oil Injected Rotary Screw Compressors GA 75L-110 VSD+

The new revolutionary compressor from Atlas Copco

Atlas Copco’s GA 75L-110 VSD + is not just a ground-breaking new compressor range, it is an operational transformation. It reduces your energy costs by 50% on average and maximizes uptime, even in the harshest conditions. Driving this next-level performance: Atlas Copco’s Variable Speed Drive, a powerful interior permanent magnet motor, and our inhouse developed Neos inverter. Thanks to its compact vertical design, the GA 75L-110 VSD + fits in even the smallest compressor room. Including yours? Discover how the GA 75L-110 VSD + can transform your operational environment today.

Key Features

- Automatic restart after voltage failure

- Internet-based compressor visualization using a simple Ethernet connection.

- Dual Pressure Set Point

- More flexibility: four different week schedules that can be programmed for a period of 10 consecutive weeks.

- On-screen Delayed Second Stop function and VSD+ savings indication

- Graphical service plan indication.

- Remote control and connectivity functions

- Control up to 6 compressors by installing the optional equalizer central controller software.

High Reliability

- 100% continuous duty cycle.

- Up to 46°C/115°F ambient temperatures.

Low maintenance

- Easy access for maintenance.

- Quality components.

- Long service interval of 4000 hours.

Silent operation

- Belt-driven element.

- Reduced noise levels and low vibration.

Full Feature (FF)

- Integrated refrigerant air dryer.

- In-line air filters.

Excellence in integrated air quality

Untreated compressed air contains moisture and aerosols which increase the risk of corrosion and compressed air system leaks. This can result in a damaged air system and contaminated end products. Maintenance costs can far exceed air treatment costs. The GA 37-110 VSD+ provides the clean, dry air that improves your system’s reliability, avoids costly downtime and production delays, and safeguards the quality of your products

On average 50% energy savings with newly designed integrated dryers

- Pressure dewpoint of 3°C/37.4°F (100% relative humidity at 20°C/68°F).

- Heat exchanger cross-flow technology with low pressure drop.

- Zero waste of compressed air thanks to no-loss condensate drain.

- Reduced operating costs.

- Environmentally-friendly characteristics: zero ozone depletion.

- Global warming potential has been lowered by an average of 50% by reducing the amount of refrigerant in the new dryer.

Download Brochure

Download Brochure